Chocolates

Cal Poly Chocolates

Cal Poly Chocolates was started in 2000 by now retired Food Science and Nutrition Faculty member Dr. Tom Neuhaus. Cal Poly Chocolates uses a 36 % milk chocolate, suitable for many applications. Made with sustainable Cacao-Trace chocolate liquor. Real chocolate made from sustainably sourced cocoa beans, Non-GMO. The finest cocoa beans are carefully selected to make pure Chocolanté chocolate, and its undeniable, wonderful taste. For our dark we are using Belcolade "The Real Belgian Chocolate" Noir Supreme 70.5% Dark Couverture Chocolate. Student employees learn about the science and art of chocolate making and some of the tools and equipment used to make all things chocolate.

Melt & Temper

We have two options that we can use for our chocolates process.

Tempering Wheel - Melting chocolate in a heating cabinet, adding "seed", and achieving and maintaining TEMPER with a tempering wheel.

Full-Auto Temperer - Melting chocolate, achieving and maintaining TEMPER all in an automatic tempering unit.

Tempering is a word that means improving the consistency, durability or hardness of a substance by heating and cooling it. Many substances, including metals, are tempered but the most important one might be chocolate. Tempered chocolate is very glossy, has a firm finish and melts smoothly at around body temperature.

Depositing our Chocolate into Moulds

We transfer our tempered chocolate from our tempering wheel or the full-auto tempering unit to our depositor. The depositor has a water jacketed hopper that keeps the chocolate at a consistent temperature to maintain temper. The chocolate is pushed out of the hopper into our chocolate moulds.

Chocolate Being Deposited into Moulds.

A close up of chocolate being deposited into our moulds. There are 5 bars being filled at a time.

Weighing our moulds filled with chocolate.

Vibrating Conveyor Belt

After the chocolate has been deposited into the moulds, we transfer the moulds to the vibrating conveyor belt. This step eliminates air bubbles within the chocolate and creates a uniform bar.

Cooling and Mould Break Out

Once the moulds have cooled, we break them out of the moulds and stack them on sheet pans. From here they will go to packaging!

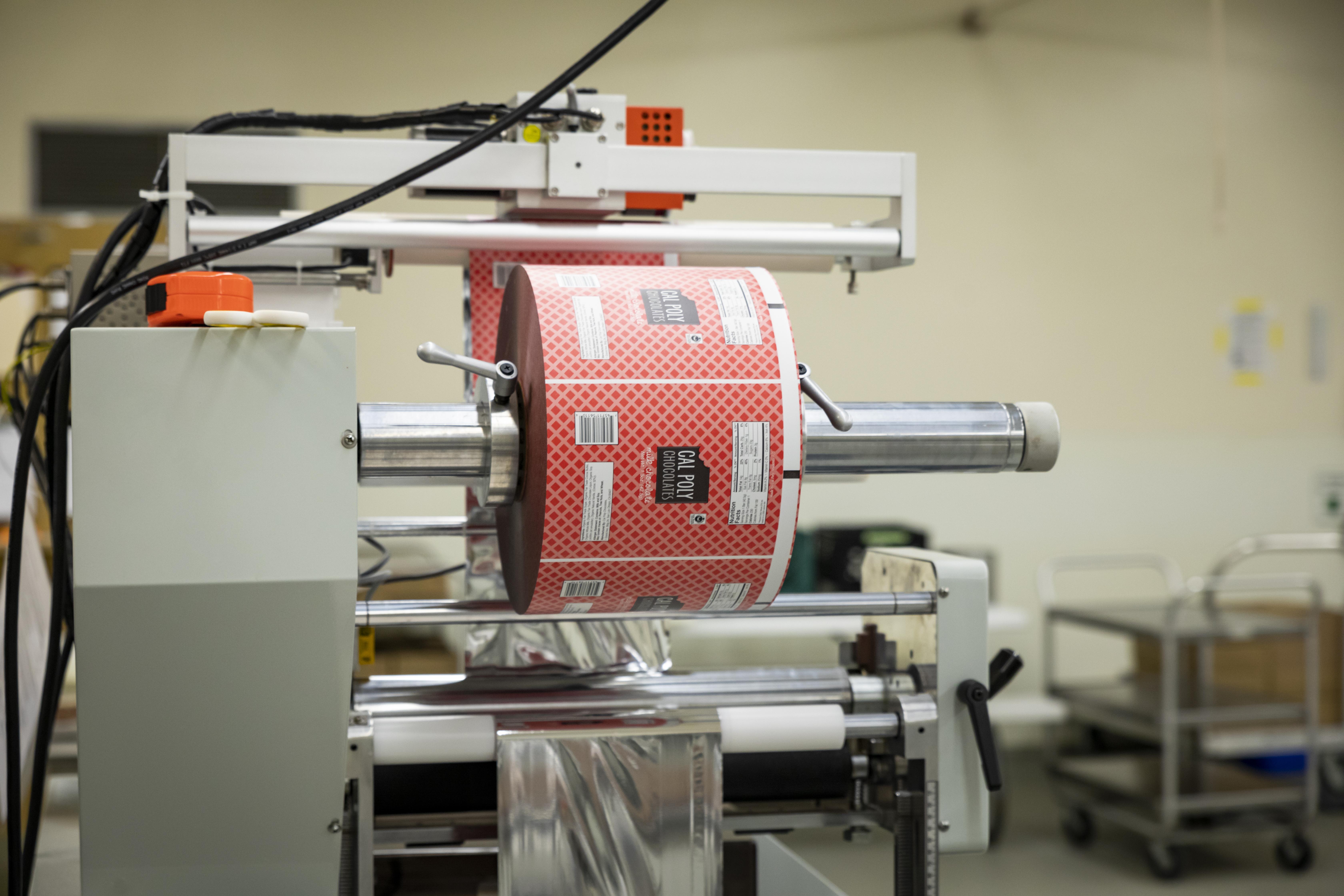

Packaging! Form, Fill, Seal

Using a form, fill, and seal machine we wrap each of our bars.

Final Step - Placing finished, wrapped bars into lug tubs for inventory and sales!

Cal Poly Chocolates has many flavors, but our Milk Chocolate Bar and Dark Chocolate Bar are our most popular. Some current, seasonal and limited-edition flavors you might see on the shelf are: Milk, Dark, Raspberry Crisp, Coffee Crunch, Peppermint Crunch, Zesty Orange, Green Tea Matcha Milk Bar, Birthday Cake, Toffee Crunch, S’mores, Coconut Crunch, Dark with Sea Salt, Peanut Butter Crunch, Deluxe Dark Peanut Butter with Salt, You're Berry Special and Hot Habanero.